Life is increasingly hectic with numerous responsibilities, leaving people with little time to wait for each drop of traditional drip coffee to fall into a perfect cup. For coffee enthusiasts, instant coffee has become an incredibly convenient alternative beverage that retains the authentic aromatic flavor of drip coffee without requiring excessive preparation time. However, few people understand how the instant coffee manufacturing process works. Follow this article below to learn more about the complete instant coffee production process!

Raw Material Selection for Coffee Production

In instant coffee manufacturing, the product is composed of coffee combined with other ingredients such as sugar and vegetable creamer to create 2-in-1, 3-in-1, 4-in-1 coffee lines. Coffee beans are carefully selected from high-quality green coffee beans (raw coffee beans) that undergo dust removal and cleaning processes. From there, the coffee beans are roasted and then ground into powder for drip brewing or processed into instant coffee.

Read more: Instant Coffee: Everything You Need to Know

Instant Coffee Production Process

The instant coffee production process is primarily carried out through the following steps:

2.1. Coffee Roasting and Grinding

After selecting the desired coffee beans, the first task we perform is coffee roasting. The roasting time according to international standards is 18-25 minutes per batch, using advanced roasting technology to help maintain the natural flavor of coffee beans. Coffee beans are evenly roasted from the inside out, without burning, beans expand evenly, and edges are not charred. Beans of both large and small sizes remain uniformly roasted with consistent color. After that, roasted coffee beans are ground into coffee powder. Coffee powder used for instant coffee production needs to be ground to a larger particle size.

2.2. Extraction

Extraction is the process of dissolving substances in coffee using hot water to create an extract solution with a concentration of soluble substances of approximately 25-35%. The extraction system and coffee extraction process proceed as follows:

- First, pour coffee into a pyramid-shaped batch extraction device with thermal insulation

- Pump hot water at approximately 80-90°C from the bottom of the tower upward to extract coffee

- When hot water passes through the coffee in the tower, the extraction process of soluble substances occurs

- These soluble substances will form a solution at the top of the tower. To help the amount of soluble substances collected at the top of the tower gradually increase, coffee powder will be continuously replaced in the towers

The extraction process is carried out multiple times, limiting the amount of fine powder that dissolves deeply into the water during extraction. The concentration of extracted coffee solution can reach 20-22%.

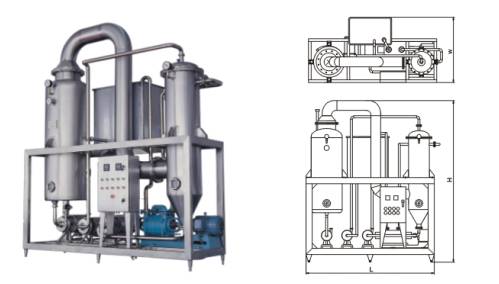

2.3. Concentration

After extraction, we cannot proceed directly to drying because at this point the coffee solution concentration is only 20-22%. To facilitate the drying process, the extracted solution must be concentrated to 30-33% concentration.

The commonly used concentration method is vacuum concentration. The coffee solution is pumped into heating equipment. Here, the water in the coffee solution absorbs heat and evaporates rapidly. The vacuum created by the barometer will draw water vapor and condense it in the condensation chamber. The process continues until the solution concentration meets the required level, then stops.

2.4. Drying

After the concentration process, coffee undergoes drying into powder form for convenient storage and use. The spray drying method is primarily used. Concentrated coffee solution is pumped to the top of the cyclone. Here there is a disc perforated with many small holes, rotating at very high speed, causing the coffee solution to enter the cyclone in mist form. Hot dry air is blown into the cyclone to dry the mist-form coffee into powder form. Instant coffee powder is collected at the bottom of the cyclone. After drying, we obtain instant coffee powder with 1-2% moisture content and a dark brown-black color.

2.5. Aroma Recovery

After the processing stages, coffee flavor gradually diminishes, especially during the spray drying process at high temperatures. Therefore, to ensure your coffee cup is deliciously full-flavored and maintains authentic coffee standards, manufacturers collect the chemical components of coffee aroma before extraction and add them back after the drying process. This is called aroma recovery.

Read more: Top 10 Instant Coffee Brands in the World

Coffee aroma recovery technology is carried out in two stages. The first is desorption, which is the process of using inert gas to collect the gas mixture. The result is a mixture consisting of N2 gas and the original aromatic components in roasted coffee. The second is the adsorption process – since coffee powder after drying is very porous, when it comes into contact with the newly collected gas mixture, it creates the most harmonious blend. From here, we obtain finished instant coffee powder.

Experience Premium Instant Coffee with Hello 5 Coffee

Nothing is more wonderful than enjoying a deliciously aromatic cup of coffee without spending too much time, right? The instant coffee production process at Hello 5 Coffee is extremely meticulous and technically precise, with the coffee roasting process being particularly crucial in awakening the inherent flavors within the beans. Now you can immediately enjoy a cup of Hello 5 instant coffee to verify this for yourself!

At Hello 5 Coffee, we are committed to bringing you the finest instant coffee products, manufactured through strict quality control processes and modern technology. Each cup of Hello 5 Coffee carries the authentic Vietnamese coffee flavor, convenient yet never compromising on quality.