Coffee roasting machines are the heart of every exceptional coffee experience. These sophisticated devices transform raw green coffee beans into the aromatic, flavorful beans that coffee lovers cherish worldwide. Whether you’re starting a coffee roasting business, managing a specialty café, or exploring wholesale coffee operations, understanding the different types of roasting machines and their heat transfer methods is crucial for success. This comprehensive guide explores the various coffee roasters available in today’s market and helps you make an informed decision for your business needs.

Understanding Heat Transfer Methods in Coffee Roasting

Before exploring specific roasting machines, it’s essential to understand how heat reaches coffee beans during the roasting process. The method of heat transfer significantly impacts flavor development and the physical characteristics of the final product. There are three fundamental heat transfer methods in coffee roasting: conduction, convection, and radiant heat.

Conduction Heat

Conduction heating involves direct thermal energy transfer through physical contact. In coffee roasting, this occurs when beans touch hot surfaces such as the drum walls or hot plates inside the machine. This direct contact method quickly transfers energy to the bean’s surface layers, contributing to robust flavor development and creating rich, caramelized notes that many coffee enthusiasts appreciate.

Convection Heat

Convection heating transfers thermal energy through moving hot air. The roasting chamber heats air, which then circulates around the beans to promote uniform roasting. Convection roasters typically offer excellent temperature distribution, ensuring an even roast profile. This method is particularly effective for creating lighter roast profiles that highlight the natural brightness and acidity inherent in quality coffee beans, making it ideal for specialty coffee operations.

Radiant Heat

Radiant heat transmits thermal energy through electromagnetic waves or infrared radiation. In roasters using this method, radiant energy passes from heating elements directly to the beans without physical contact. While this creates distinctive toasty flavors, it generally provides less temperature control compared to conduction and convection methods.

4 Different Types of Coffee Roasting Machines

Direct Fire Coffee Roasters

Direct fire coffee roasters represent one of the traditional approaches to coffee roasting. These machines use direct flame heating of the drum, which transfers warmth directly to the coffee beans through contact. This method primarily relies on conduction heat and can reach high temperatures quickly for rapid roasting results.

The primary advantage of direct fire roasters is their ability to create deeply caramelized beans with rich, bold flavors. The intense heat brings out complex taste profiles that appeal to those who prefer traditional roasting methods. However, this intensity can sometimes result in uneven roasting, where some beans may become overly scorched while others remain underdeveloped. Success with direct fire roasters requires skilled operation and constant monitoring throughout the roasting process.

For wholesale coffee operations focusing on traditional flavor profiles, direct fire roasters can be an excellent choice when operated by experienced roasters who understand the nuances of temperature control and bean movement.

Semi-Fire Semi-Hot Air Coffee Roasters

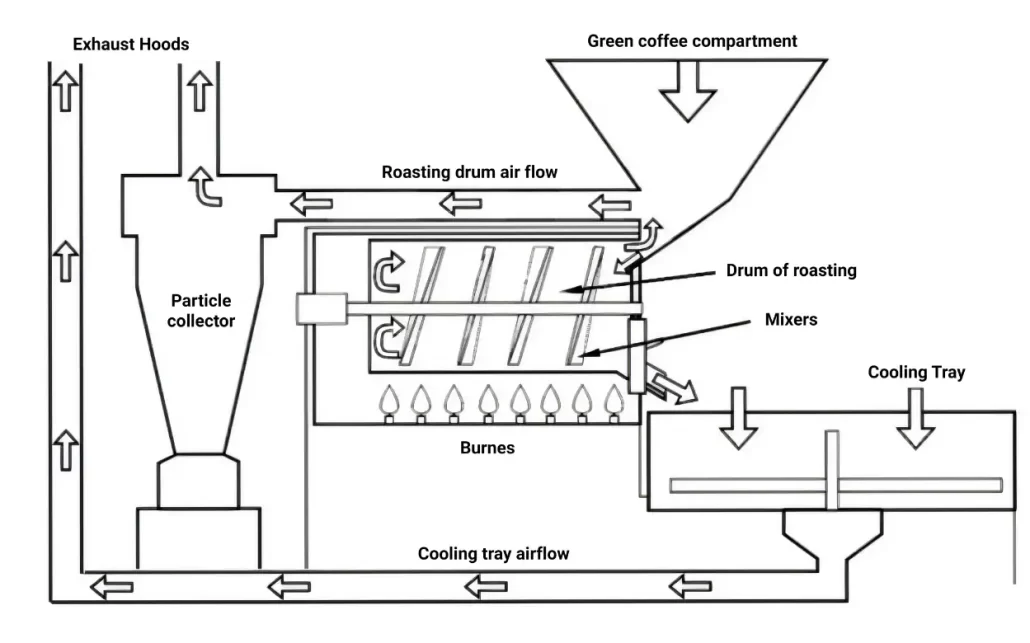

Semi-fire semi-hot air roasters represent the most popular category of drum coffee roasters in today’s market. These versatile machines combine the best of both worlds, using a rotating drum heated either directly with flames or via electrical heaters. As beans rotate inside the drum, hot air simultaneously circulates throughout the roasting chamber, ensuring even heat exposure. This dual approach combines conduction and convection heating to maintain deep flavors while providing uniformity through the hot air system.

Key Advantages of Semi-Fire Semi-Hot Air Roasters:

- Even Heating: The combination of conduction and convection heat working simultaneously ensures consistent roasting across all beans, eliminating the uneven roasting issues often associated with traditional drum roasters.

- Rapid Temperature Control: Direct flame heating allows temperatures to rise quickly, reducing overall roasting time and increasing production efficiency.

- Flexible Controls: The hot air system provides precise temperature regulation that can be customized for different coffee bean varieties, origins, and desired roasting levels. This flexibility is invaluable for specialty coffee roasters working with diverse bean selections.

- Rich Flavor Development: Conduction heat penetrates deep within coffee beans, creating rich and robust taste profiles, while the hot air system preserves the beans’ original aroma and natural acidity levels.

- Versatility: These roasters excel at everything from light to dark roasting applications, making them ideal for businesses offering diverse coffee profiles to their customers.

- Energy Efficiency: The hot air system maximizes heat energy utilization while reducing power consumption, lowering operational costs over time.

For businesses like Hello5coffee.com specializing in premium and specialty Vietnamese coffee wholesale and export, semi-fire semi-hot air roasters offer the perfect balance of quality control, production efficiency, and flavor development. These machines can handle the demands of commercial-scale roasting while maintaining the consistency required for premium coffee exports.

Read more: Top 5 Best Coffee Roasters in Vietnam

Hot Air Coffee Roasters (Fluid Bed Roasters)

Hot air coffee roasters, also known as fluid bed roasters, rely exclusively on convection heating. In these innovative machines, beans are suspended in currents of hot air that circulate around them, creating a uniform and rapid roast. This method provides excellent control over both temperature and airflow, resulting in even roasting and reduced processing time.

The primary advantage of hot air roasting is its ability to achieve lighter, more delicate flavor profiles characterized by brighter acidity and cleaner finishes. These roasters are ideal for highlighting the unique characteristics of different coffee origins, making them popular among specialty coffee roasters who want to showcase the terroir and distinctive notes of premium beans.

Hot air roasters work exceptionally well for light to medium roast enthusiasts who appreciate the subtle flavor nuances that different origins provide. However, achieving certain darker roast profiles or roasting specific bean types may present challenges. The fast roasting times require experienced operators who can carefully manage the process to avoid uneven results or underdevelopment.

For exporters focusing on specialty-grade Vietnamese coffee with distinct regional characteristics, hot air roasters can effectively highlight these unique flavor profiles, appealing to international buyers seeking exceptional single-origin coffees.

Infrared Coffee Roasters

Infrared coffee roasters represent a more modern approach to coffee roasting, utilizing infrared radiation to heat coffee beans. Heating elements produce infrared waves that penetrate beans from within, warming them quickly and consistently while creating unique flavor profiles. The key benefit of infrared roasting is efficiency—beans can be heated rapidly and uniformly without compromising flavor quality or aroma integrity.

Infrared roasting offers several advantages, including faster roasting times, consistent heat penetration, and energy efficiency. The technology allows for precise control once mastered and can produce distinctive flavor characteristics that differentiate your coffee in the market.

However, infrared roasters do have limitations. They may not provide as much control over the roast profile as traditional drum or hot air roasters. Additionally, mastering the technique requires an extended learning curve, as operators must carefully monitor all parameters during roasting to prevent over-caramelization or scorching of beans.

Sample Roasters

Sample roasters deserve special mention as essential tools for coffee businesses. These small-capacity machines, typically roasting between 50 to 300 grams per batch, are designed specifically for testing green coffee quality, developing new roast profiles, or experimenting with different beans before committing to large-scale production.

The greatest advantage of sample roasters is their ability to minimize waste during testing and development. Coffee buyers, quality control managers, and roastmasters can evaluate multiple bean varieties or roast profiles without consuming large quantities of valuable inventory. Sample roasters often provide high precision in replicating industrial roasting conditions, making them invaluable for wholesale operations that need consistent quality across large production runs.

For a company like Hello5coffee.com working with premium Vietnamese coffee exports, sample roasters are indispensable tools for quality assurance, buyer presentations, and developing customized roast profiles for international clients.

Choosing the Right Coffee Roasting Machine

Selecting the appropriate coffee roasting machine depends on several critical factors that align with your business objectives and operational requirements.

- Production Scale: Determine your daily or weekly roasting capacity needs based on current demand and projected growth. Home roasters handle 50-500 grams per batch, while commercial operations may require machines capable of roasting 15kg to several hundred kilograms per batch.

- Investment Budget: Consider not only the initial purchase price but also installation costs, ongoing operational expenses, maintenance requirements, and energy consumption. Higher-end machines often justify their premium through superior consistency, efficiency, and longevity.

- Roast Profile Requirements: Different machines excel at different roast levels and flavor profiles. Consider whether your focus is on light specialty roasts, traditional darker roasts, or the flexibility to offer diverse profiles to meet various market demands.

- Operator Expertise: Some machines require significant training and experience to operate effectively, while others offer more user-friendly controls and automated features. Assess your team’s current capabilities and willingness to invest in skill development.

- Space and Infrastructure: Evaluate your facility’s available space, electrical capacity, gas connections, and ventilation systems. Industrial roasters require substantial infrastructure investments beyond the machine itself.

- After-Sales Support: Prioritize manufacturers or distributors offering comprehensive warranty coverage, readily available spare parts, and responsive technical support. Reliable service prevents costly downtime that can disrupt your business operations.

The world of coffee roasting machines offers diverse options, each with distinct characteristics, advantages, and ideal applications. Direct fire roasters create bold, traditional flavors through intense conduction heat. Semi-fire semi-hot air roasters provide the perfect balance of flavor depth and roasting consistency, making them the most popular choice for commercial operations. Hot air roasters excel at creating bright, clean profiles that showcase origin characteristics. Infrared roasters offer modern efficiency and unique flavor development. Sample roasters serve as essential tools for quality control and product development.

For businesses engaged in specialty coffee wholesale and export, like Hello5coffee.com, understanding these different roasting technologies is fundamental to delivering consistent, high-quality products that meet international standards and customer expectations. The right roasting machine becomes a strategic asset that enhances your coffee’s value proposition, operational efficiency, and market competitiveness.

By combining quality Vietnamese green coffee beans with appropriate roasting technology and skilled operation, you can unlock the full potential of your coffee, creating exceptional products that resonate with coffee enthusiasts and connoisseurs worldwide. As the global coffee industry continues to evolve, staying informed about roasting machine technologies and techniques will help you maintain excellence and innovation in your coffee offerings.